Pressure sensor feedback loop

How to study bacteria by microfluidics

Controlled microfluidic sample injection

Preparation of PLGA nanoparticles by flow focusing

All our application notes: here!

Mechanical cell compression

Performance of polymeric skin adhesives during perspiration

Sensor Reader: Pressure, Flow & Bubble Detection

Sensor reading unit

Fast & precise

Down to 5 ms response time and 16 bit signal resolution

Simultaneous reading

Connects up to 4 sensors

Compatible

ELVEFLOW's pressure & flow sensors

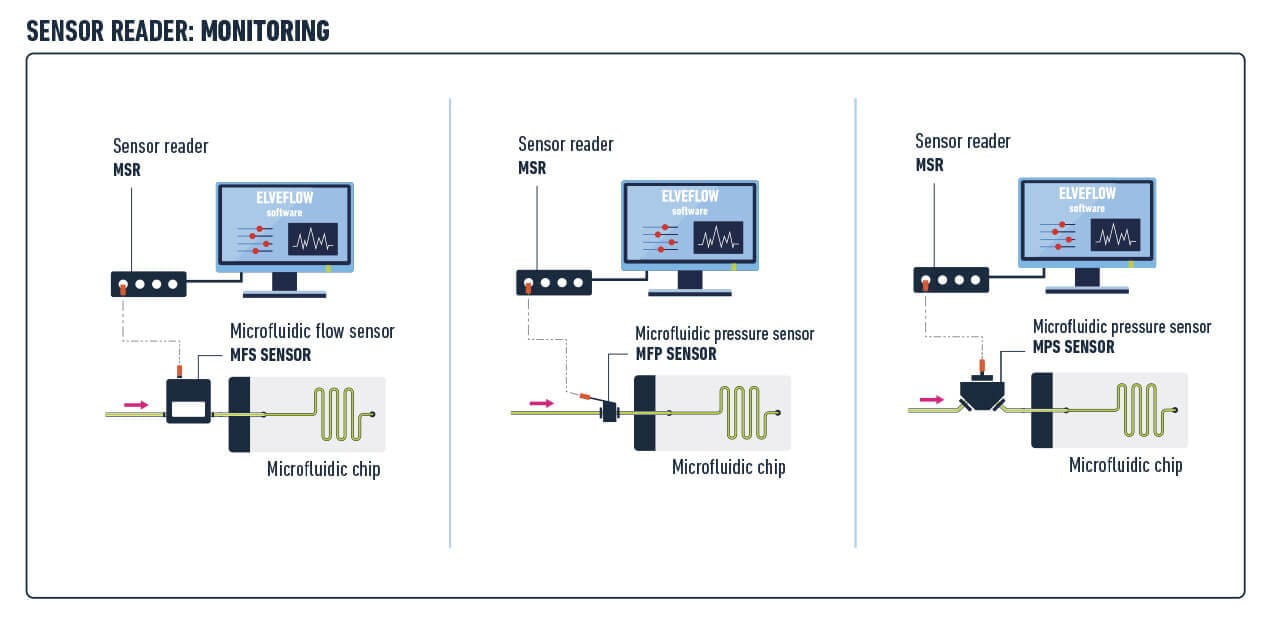

MONITOR THE MEASUREMENT OF ALL YOUR MICROFLUIDIC SENSORS

Connect pressure and flow sensors wherever you want in the setup to closely monitor your microfluidic experiment.

The Sensor Reader module allows you to control 4 sensors simultaneously. Additionally, our software allows controlling several Sensor Readers simultaneously.

The MSR is the ideal supplement to the OB1 flow controller should you need high control over your experimental parameters.

Benefit in an optimal manner from the performance of Elveflow® Sensors with the Sensor Reader acquisition interface. The open interface Sensor Reader also allows you to use third-party sensors.

Fast and precise

With an acquisition sampling rate of up to 200 Hz and an 16 bit resolution, the Sensor Reader allows you to easily conduct experiments involving monitoring or controlling a physical parameter with analog and digital sensors in real time.

Wide sensors compatibility

See Elveflow® fully compatible pressure sensor & flow sensor below

Noise reduction

An embedded analog 60 Hz low pass filter function can be activated on each channel independently to reduce sensor noise.

PERFORMANCE

Our Sensor Reader achieves an 16 bits resolution at up to 200 Hz sampling rate and a sub-resolution noise, for accuracy levels on your sensor measurements down to 0.05% of the full scale and a response time down to 5 ms.

Sampling rate up to 200 Hz

Resolution :from 9 to 16 bits

Input range : 0 – 10 V

Fully compatible with other Elveflow instruments

Measurement noise below resolution

Noise reduction function with a 3rd order 60 Hz low-pass filter

ELVEFLOW® PRESSURE & FLOW SENSORS – FULLY COMPATIBLE

We have already selected a wide range of integrated sensors fitting microfluidic applications.

Flow Sensors (MFS)

Resolution 1,5 pL/sec

Ranges from 0.07 to 5000 μL/min

Accuracy down to 0.2 % of Full Scale

4 ranges from 5 psi (340 mBar) to 100 psi (7 bar)

All our sensors are provided with an M8 electrical connection and can be used with the Sensor Reader. We also provide all the microfluidic connector kits necessary to start your experiment.

Applications

- All our research summaries: here!

Microfluidic for cell biology: Concepts and methodologies

Thermoelectric sensor

Microfluidics for point-of-care diagnostic devices

All our reviews: here!

Publications

For all the publications using our products, please click here.

For all the application notes and reviews based on our product, please click here.

ESI is Elveflow’s more advanced software interface, built to make experimenter’s life better. It is perfectly adapted, from simple setups control to very advanced setups and workflows automation. It embarks several modules that make time-consuming and painful tasks so simple. It comes with SDK libraries to control the Elveflow system with your own code (C++, Python, MATLAB®, LabVIEW®)

| SKU | 505889 |

|---|

FAQ

1. ELVEFLOW’S SINGLE SOFTWARE (ESI)

Monitor and automate your setup using our ESI software that allows you to measure, control and automate your experiment using only one interface.

2. FLOW SENSOR (MFS) OR PRESSURE SENSOR (MPS)

Place the sensors anywhere you want on your fluidic path and electrically connect your sensors to the Microfluidic Sensor Reader.

Thanks to their small footprint, sensors can be placed anywhere within your fluidic system.

3. MICROFLUIDIC SENSOR READER (MSR)

Connect the sensor reader to your computer via USB and monitor it using the Elveflow® Smart Interface

4. CHIP / CAPILLARY

Add you chip to complete the standard setup. In this position, the sensor directly measures the pressure entering the microfluidic chip. You can add another pressure sensor at the chip outlet in order to get the difference in pressure and/or the microfluidic resistance.

The following table summarizes the main features of the Elveflow® MSR Microfluidic Sensor Reader.

| Sensor Reader Unit | Specifications |

| Number of sensors connections | up to 4 |

| Sensor connectors | M8 female (4 pins) |

| USB reading current min – max | 200 mA – 800 mA |

| Sensor power supplies voltage (2 power supplies tunable independently each of which feeding 2 sensors) | 5 – 24 V |

| Max total power on the 4 channels | 0.9 W |

| Sensor Inputs | |

| Impedance | 1 MΩ |

| Acquisition frequency | 200 Hz |

| Acquisition resolution | from 9 to 16 bits |

| Input range | 0- 10 V |

| Resolution (1 bit) | 5 mV |

| Noise (full band) | 5 mV rms |

| Compatible sensors | Elveflow MFS flow sensor, MPS pressure sensor, MFP FlowPlus pressure sensor, MBD bubble detector, other sensors |

Non-contractual information, may be changed without notice

SENSOR READER SIZE: without connectors (length x width x height): 91 x 69 x 29 mm

WEIGHT: 320 g